Why Air Flow Is Important in a Laboratory Classroom: A Case Study

College science building addition has ventilation issues in their lab requiring further investigation of building operation and HVAC system design. This project’s scope includes adding a new laboratory classroom building to an existing classroom and office building on a college campus.

The current building design included fan coil units with dedicated outside air units to provide building ventilation. A central station air handling unit served the new addition. The expansion contains double doors on the first and second floors of the building open to the existing building. The expansion also includes two sets of double doors that open to the outside. One new air handling unit serves the expansion and includes 14 VAV boxes with hot water reheat. The air handling unit consists of a preheat coil, cooling coil, fan, outside air damper, return damper, airflow measuring station, and associated controls. They designed the air handling unit system for 15,000cfm with 6,000cfm of outside air. The user manually controls the laboratory fume hoods and general exhaust fans, and the light switches interlock with the restroom and janitors’ closet fans.

How was the original sequence of operation intended to work?

The original sequence of operation required the air handling unit in the new addition to modulate based either on space CO2 sensor set points or maintain a positive 0.01″ of pressurization in the new building addition.

During the initial commissioning of the building, we noticed that the air handling unit was operating at 70% VFD speed with

the outside air damper 100% open, trying to meet the building pressure requirement. Since the new addition only had two sets of double doors that opened to the outside of the building, and the exhaust fans were all turned off, we had to figure out where that outside air was going. Field investigation revealed that the owner was propping the double doors between the existing building and the new addition open. As a result, the volume of the existing building and the older construction created thousands of CFM of outside air that pumped into the existing structure without meeting the DP set point in the new addition.

The air handling unit operating more than the designed outside air capacity has several issues. First, the air handling unit will lose the ability to control humidity in the summer. The increased enthalpy of the outside air will raise the summer discharge temperature from the scheduled 51 degrees Fahrenheit to a higher temperature with less dehumidification. The higher space humidity will lead to discomfort and the possibility of mold. Second, the additional outside air will cost a lot more energy to cool. Finally, the increased outside air can cause issues with the room pressure relationships during building operation.

What are the primary considerations with laboratory classroom ventilation?

Many high schools and colleges teach in spaces that utilize fume hoods. The chemicals and processes used in these spaces have a broad and varying impact on the required HVAC provisions. These spaces have many stringent and often competing criteria. For example, some areas include fume hoods that tend to be noisy while also needing quiet for teacher instruction. These spaces often include projectors or large television screens for education and laboratory desk spaces with electrical outlets so students can charge their laptops while attending class. These spaces present varying challenges from a design, operational, and commissioning perspective. The case that we will be looking at is a laboratory classroom in an existing college science building.

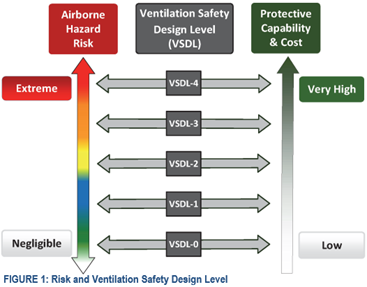

At what levels is air circulation safe?

The air circulation within a laboratory can fall into several categories based on ASHRAE: Laboratory Ventilation Design Level (LVDL).[1] Figure 1, to the right, depicts the risks associated with airborne hazards and the levels of protection associated with the range of LVDLs.[2] Those categories range from 100% outside air with zero airside energy recovery to 100% outside air with energy recovery, allowing air circulation with minimum outside air and air change rates. Laboratory spaces in high school and college settings hold classes while occasionally using fume hoods.

Since the fume hoods are not constantly in use, recirculation of room air is preferred to save on operating expenses. In the case study we will examine, the laboratory staff determined low-level toxic chemicals for use. Thus, allowing air recirculation within the classroom space to be safe.

A Remedy for Air Flow Issues and Future Staff Changes

To continue testing, we closed the double doors that connected the new addition to the existing building—the outside air damper in the air handling unit closed to a minimum position with these doors closed. We worked with the Testing and Balancing contractor and experimented in the field to determine that a building pressure of 0.02″ was the appropriate value to both get positive building pressurization without holding the outside doors open. We worked with the controls contractor to update the building pressure set point in the sequence of operation for the air handling unit. We spoke with the owner about the importance of keeping the doors between the new addition and the existing building closed. This building will be operational for a long time. Due to the life span of the building, the information regarding the importance of keeping those doors closed must pass to future staff; however, there is a possibility that information may be lost. To help minimize the issues associated with propping the doors open, we worked with the engineer. They modified the sequence of operation to include a maximum position limit for the outside air damper based on VFD speed. This damper position limit will prevent the air handling unit from operating in 100% outside air mode for an extended period if the doors between the new addition and the existing building are propped open again. When troubleshooting issues in the field, it is essential to find solutions that work both in the short term for the current occupants of the building while also being robust enough to work for people who will not occupy the building until years in the future.